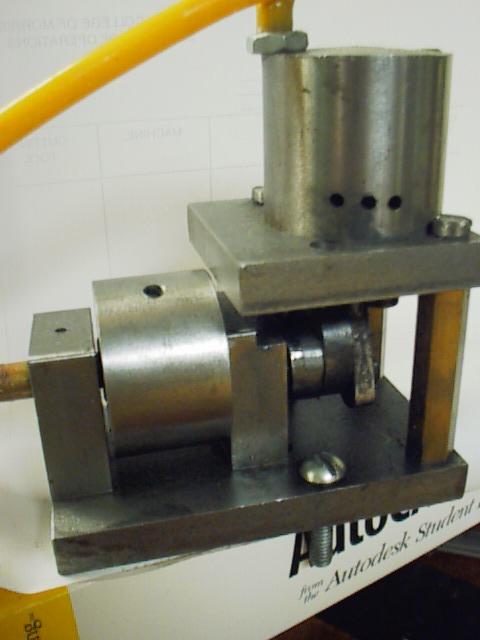

Compressed air enters the engine via the top of the head (see the yellow hose in the second photo of our project engine).

This air presses down against a steel dowel that slides in a hole parallel to the cylinder. The air pushes the dowel (valve)

against the cam. As the cam rotates to it's "low" position, the dowel is forced down (by the air.....there's no actual valve spring).

As the dowel moves down it uncovers a small transfer hole that allows the compresssed air to enter the cylinder (and push the piston down).

When the piston reaches it's lowest point (BDC), it uncovers the exhaust ports (the three holes near the base of the cylinder in both photos).

Excess compressed air escapes. This is not the most efficient system (the engine does consume some power compressing trapped air as it travels

up towards TDC), but it is a simple and reliable system (somewhat like 2-cycle gas engines).

The engine operates by "pressure differential". There is some pressure above the piston as it raises (a bad thing), but there is much more when

air is admitted via the transfer port, pushing the psiton down.

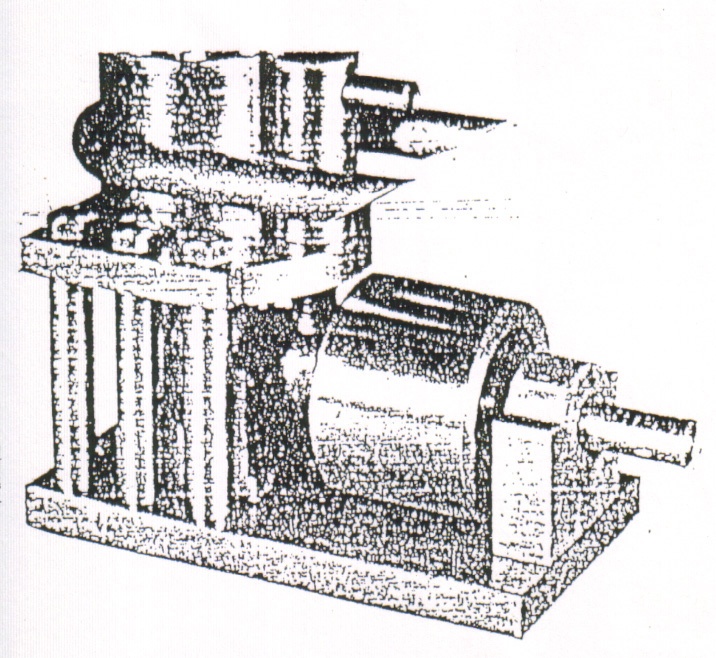

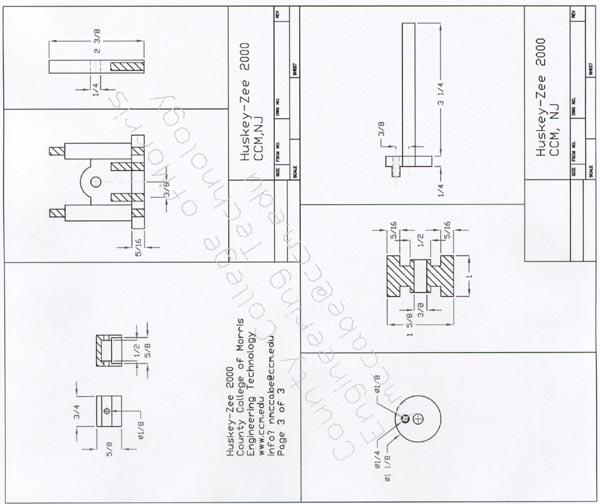

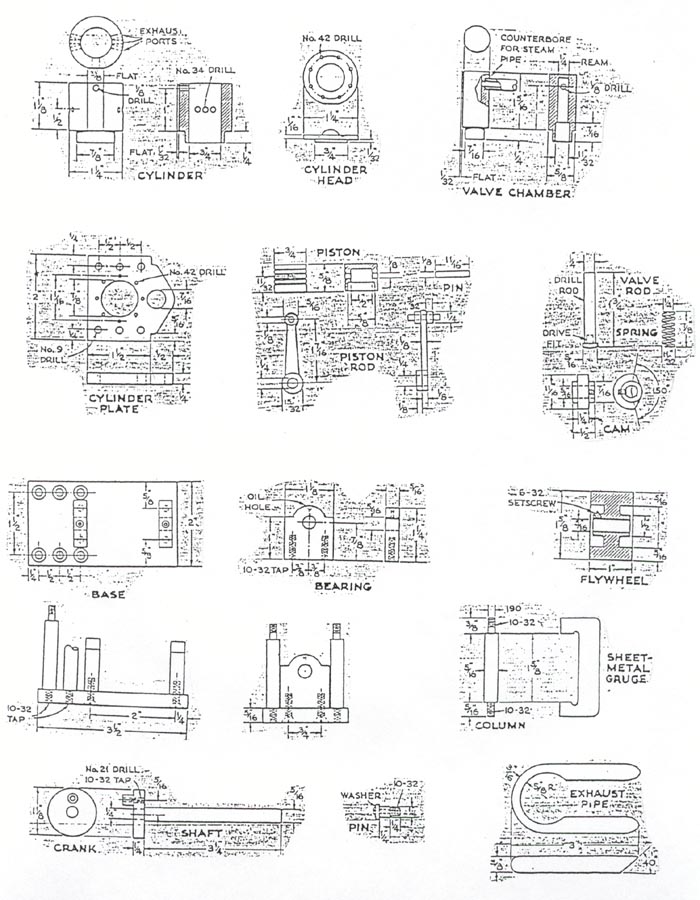

Black and white image at top left is original...the two color photos are our

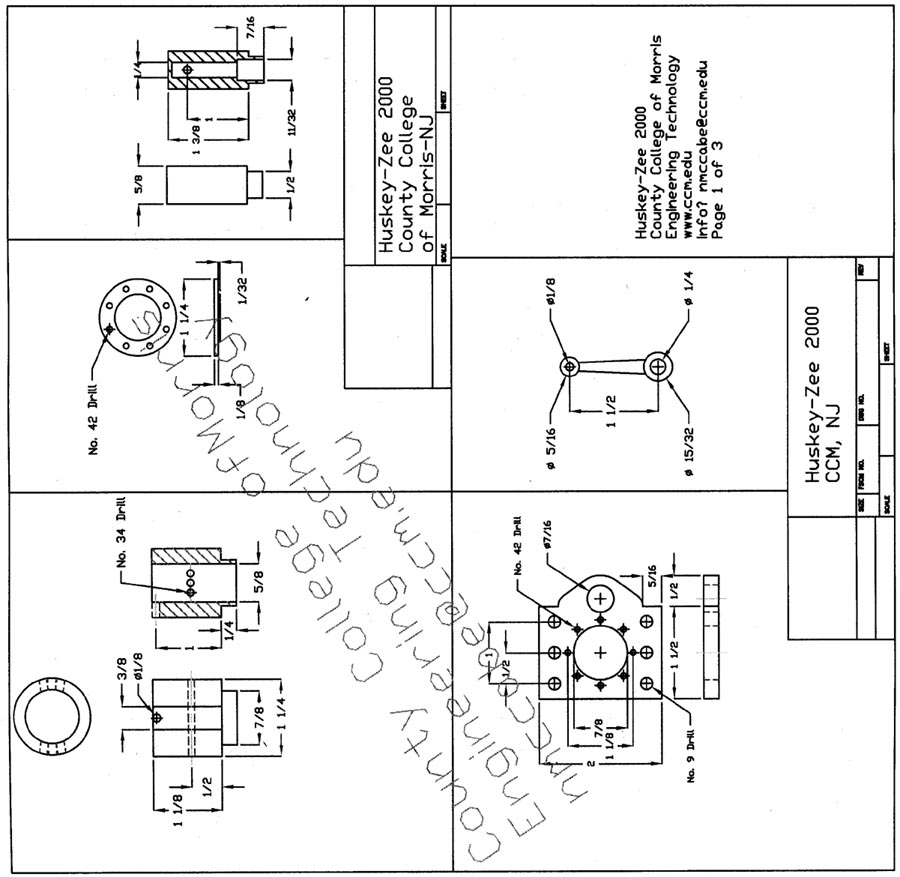

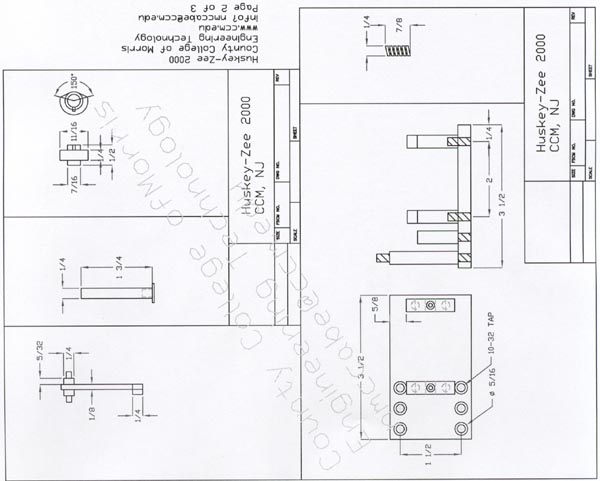

modern version. Sheet#1 Sheet#2 Sheet # 3 Part of the original (50 year old) magazine plans. Nial

McCabe's Home Page for model steam engines and plans Return to my main homepage