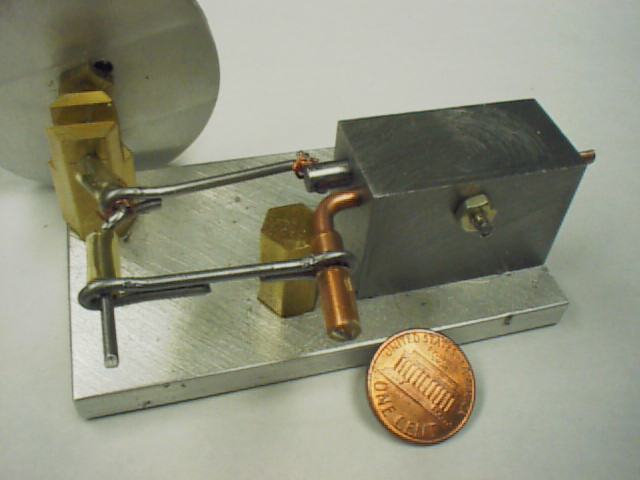

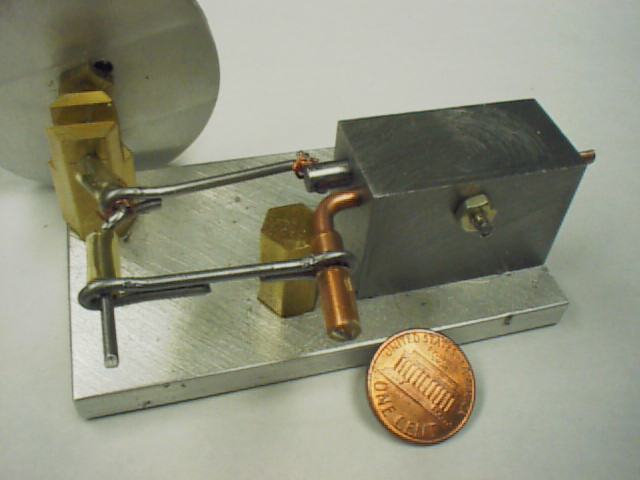

Mer-Zee Engine

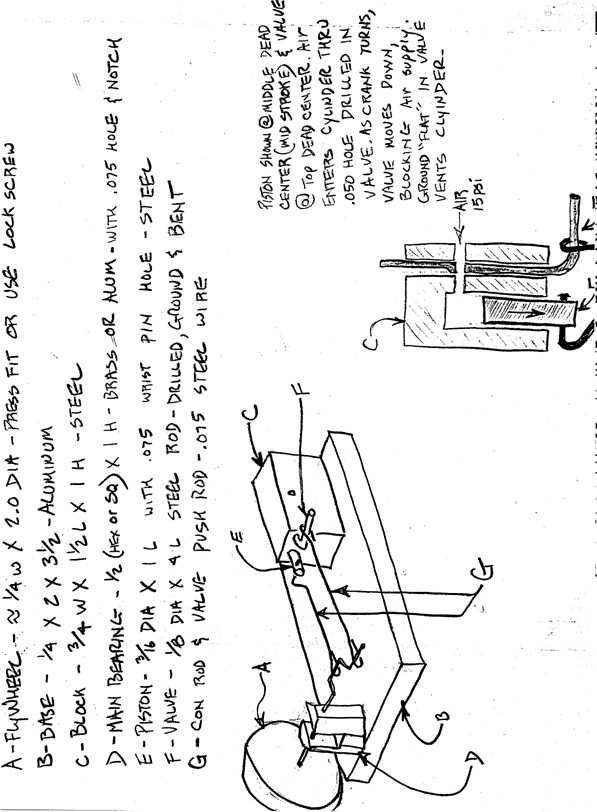

Here's a simple slide valve mill-type engine that we made from scrap bin parts. Tricky part is making the coat-hanger-wire crankshaft. Stroke for the piston is about .375". Stroke for valve is about .187". Valve "throw" on crankshaft must be 90 degrees "out-of-phase" with the piston "throw" (to understand this, consider bicycle pedals 180 degrees "out-of-phase"). I usually make 2 or 3 cranks before I get one right. The shorter brass hex in the photo is simply a support for the valve......without this support, the valve would flop over (due to the bend) and cause misalignment for intake and exhaust. Valve has a small hole (~.050") drilled through it that only lines up with air supply when piston is at Middle-Dead-Center and heading down (to BDC). When piston is at Middle-Dead-Center and heading up (to TDC), a "flat" in valve moves into position (to vent cylinder). Rods are located on crank using small press-fit plastic tubing. The flywheel in the photo is a bit too big; it was borrowed from another engine. We made a smaller one later on. Quaint, hand-drawn plans were done for fun......will try to CAD version of this at some point.