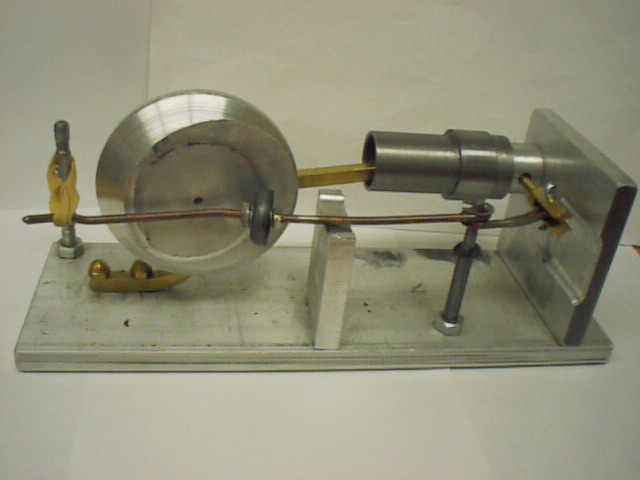

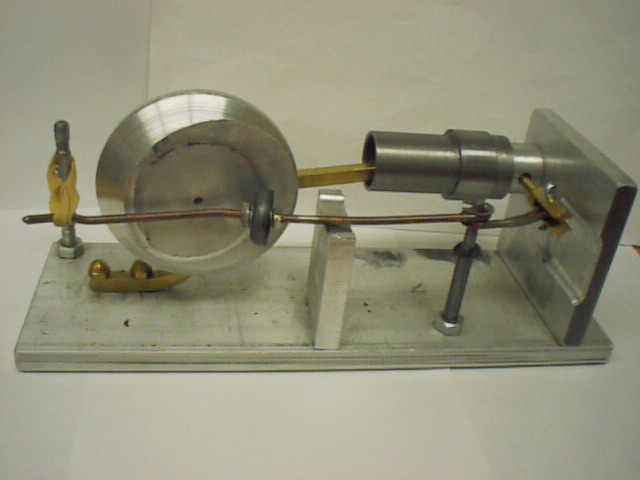

McGoose-

This is one of the least efficient, but most interesting engines we've built. It runs quite slow and steady, with decent torque but requires an enormous amount of air to do so...won't run on less than 50 psi (and then, at just ~200 RPM). Built almost entirely from scrap bin parts, it uses a large .75 bore and quite long stoke. Main bearing is a spindly looking piece of 1/4 by 1/4 brass with a gentle 90 degree bend in it. best part of the engine is the swash plate "cam" the operates the valve. Swash plate "follower" is a model airplane wheel connected to the long 1/8 steel (welding rod) "rocker arm". Arm was so long, we needed a midpoint support for it. Opposite end of rocker arm connects directly to valve (made from brass hex stock). Valve "spring" is large rubber band (they last about two hours of running time).