V-4 Engine

Here's a nice little 4 cylinder engine that uses the same basic valve layout as the "Runner" engine (seen elsewhere on this site). We would not advise that anyone try to build a project this complex as a first effort. It would be an excellent type of project for a reasonably skilled (and patient) person. At the moment, we do not have actual drawings for this project (but we are hoping to post some basic layout sketches). This project was entirely designed by Bobby C. , a first year Mechanical Engineering Technology student at CCM. Most components were built from T6-6061 aluminum. The engine uses a two pin steel billet crank turned on a lathe (using a four-jaw chuck). The aluminum billet crank (with pure circular lobes rather than true cams) was built in a similar fashion. Valves were made from ordinary construction nails (you can see some of the nail-points in the valve train pictures). Valves are actuated by rocker arms pivoting on two of the long overhead shafts. Cam followers and springs actuate the rocker arms. The copper tube "header" pipe is actually an intake system. Exhaust leaves through the valve side of the heads, directly into the atmosphere. Engine runs very smooth and will often self-start. Idle is ~ 200 RPM at ~ 4 psi. 30 psi will yield ~ 2500 RPM (and it has kind of a nice smooth sound similar to a miniature Honda 4 cylinder motorcycle).

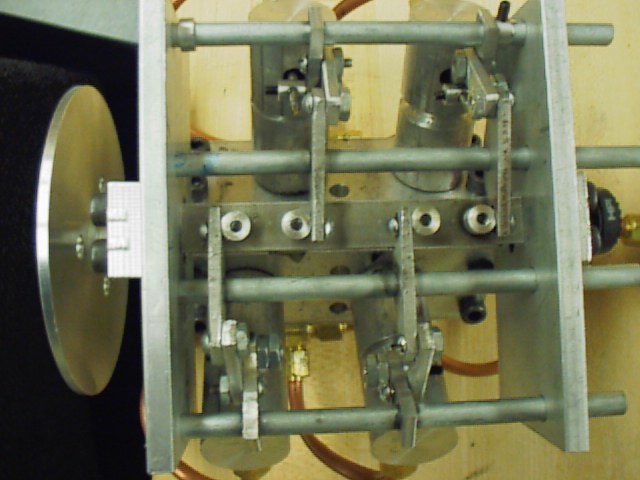

Picture above shows valve gear from top view.

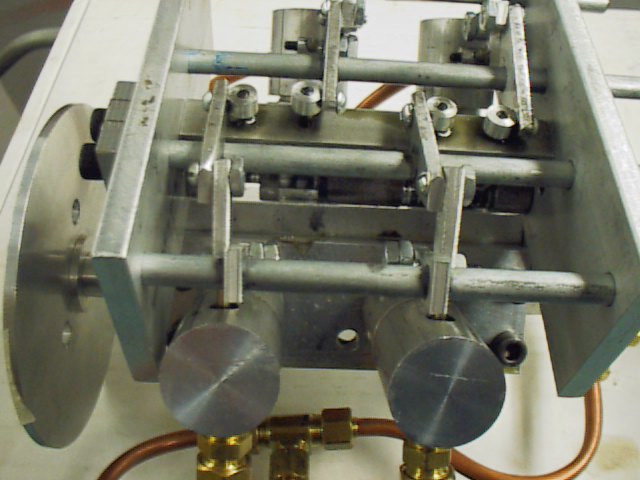

Copper intake "header" is clearly visible above.

Cam and one lifter is clearly visible between cylinders (above).

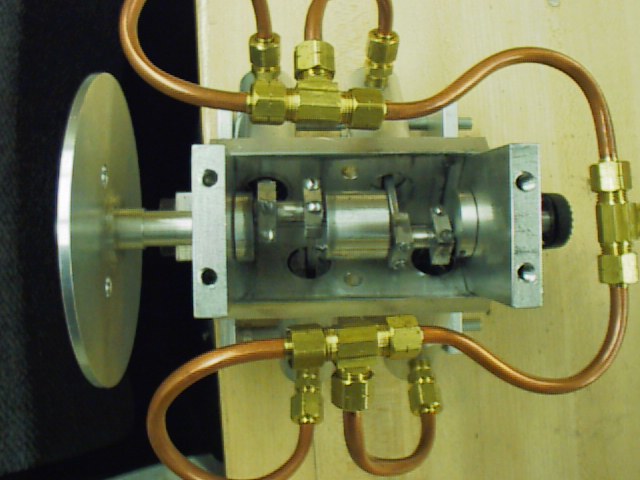

Underside of engine showing two-pin billet crank and "doghouse" block construction (of 3/8" aluminum plate).